Many industrial manufacturing plants require the use of dangerous chemicals in their operations. Things like strong acids, resins, polymers, solvents and caustics are common in industrial applications. Although these substances are highly dangerous on their own, they are necessary to the manufacturing process for many common household goods and for other industrial processes.

One of the main issues that arises from using these dangerous chemicals is how to handle the material safely. This process can be challenging, but is essential for having a thriving business and for preserving our natural environment.

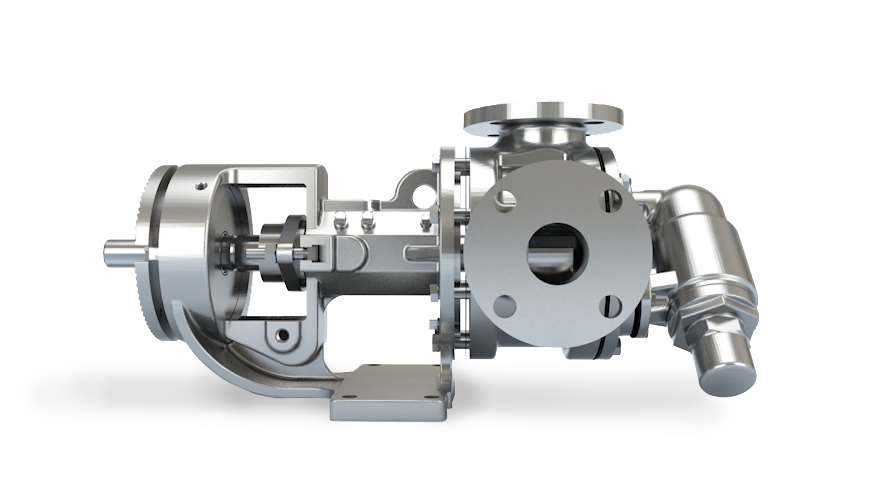

Internal gear pumps, like the E Series and G Series from EnviroGear , offer reliability and cost-effectiveness in handling and transferring potentially harmful chemicals. These pumps work by drawing fluid into the pump by creating a vacuum environment. This ensures that the liquid flows smoothly through the pump without any back-and-forth action. This positive displacement motion represents one of the best options available today for processing the many different types of chemicals that are used in industrial facilities throughout Australia and around the world.

Another key benefit of internal gear pumps is that they are capable of handling a wide range of chemicals and materials, even those that are especially thick and viscous. These materials include things like:

Because internal gear pumps have few moving parts, they are quite easy to maintain and repair, resulting in minimal downtime when they need to be serviced. This way, manufacturing facilities can keep their workflow moving as smoothly as possible.

There are two primary categories of internal gear pumps for you to choose from: seal-less magnetic drive pumps and pumps with a mechanical or packed gland shaft seal. Seal-less internal gear pumps effectively eliminate the risk of leakage and greatly reduce mechanical wear on the system overall. These types of pumps are considered to be the safest available, both for your work force and the environment. Pumps with shaft seals are also highly effective and offer precise, consistent transfer of fluids. This makes them ideally suited to the chemical and pharmaceutical industries, which have exacting specifications for their chemical transfers.

You have many options to choose from when it comes to internal gear pumps. If you are not sure exactly what you need, the extensive options available can seem overwhelming. Here at Allied Pumps, we will gladly assist you in narrowing down your choices. We’ll carefully evaluate the specific needs of your organisation before making a recommendation. Once you have made your final decision, we’ll get your system up and running as soon as possible so that you can get back to work right away. Going forward, we can assist with any ongoing maintenance and repair needs to keep your system in top working order. Get in touch with us today to learn more.

Contact us to learn about how we can help you with your pump needs.

CALL US NOW EMAIL US