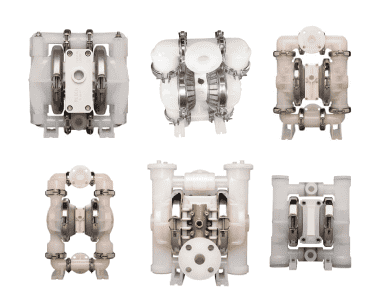

When Jim Wilden first added a plastic pump series to his product portfolio, he designed it with what he knew best: a clamped pump. Incorporating the same benefits as a clamped metal pump, these plastic versions offer a simple, rugged design that is ideally suited for chemical applications. Engineered with ease of maintenance in mind, clamped plastic pumps are simple to install and are made for quick serviceability, allowing the pump to be taken apart and put back together with only a single tool. Proven by the test of time, hundreds of thousands of Jim Wilden’s clamped plastic pumps have pumped billions of gallons of fluid on an annual basis.

Contact us to learn about how we can help you with your pump needs.

CALL US NOW EMAIL US