* 1 cycle = 2 strokes

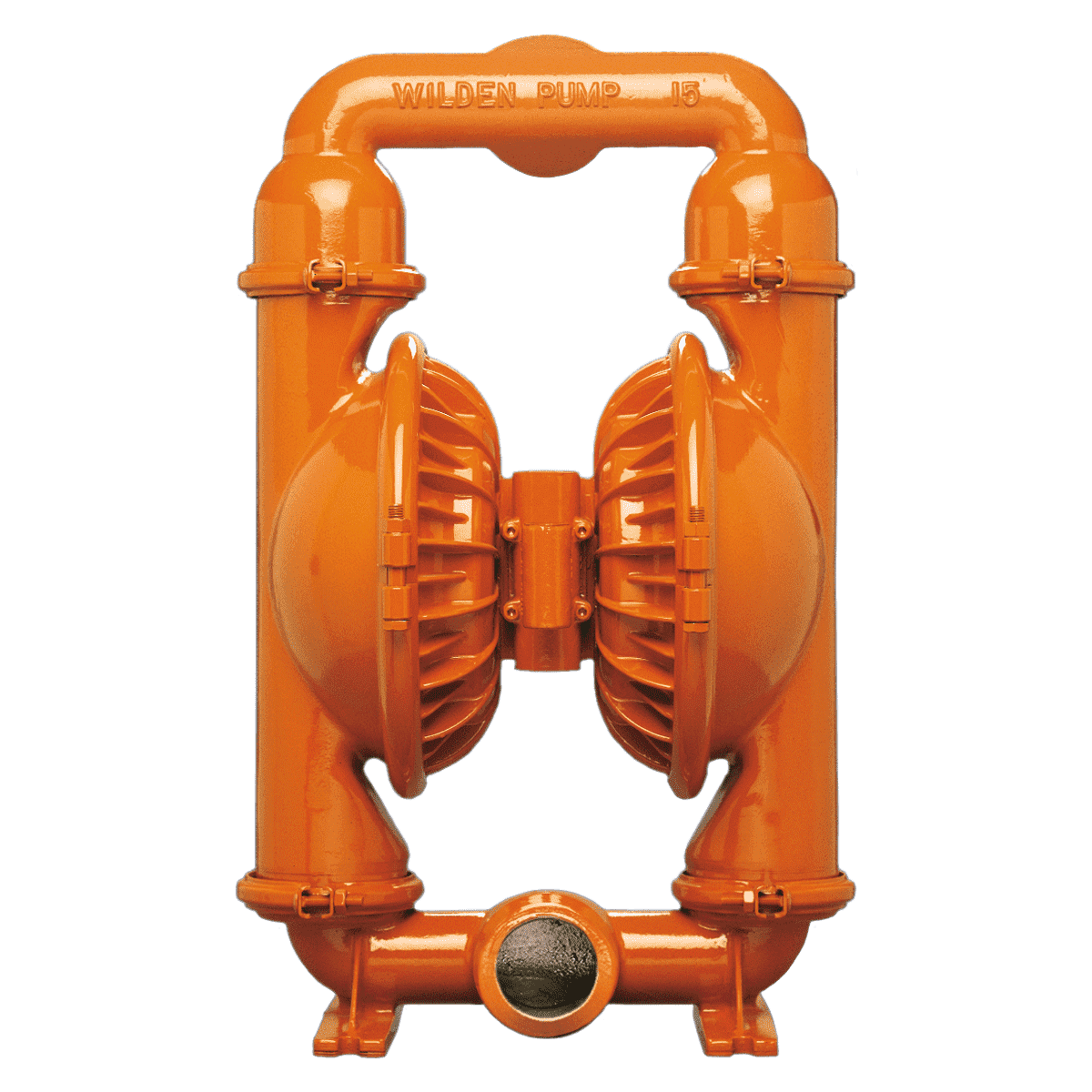

Wilden® Stallion® Series Air-Operated Double-Diaphragm (AODD) Pumps are ideally suited for rugged mining applications thanks to their unique ability to handle solid-laden mining slurries with ease. Furthering the Stallion Series pump’s ability to handle the toughest mining applications is a robust design featuring a large internal clearance and flow-through path for large-solids passage that prevents the pump from clogging. The Stallion Series is also designed with a polyurethane screen base at its inlet to provide additional durability.

Stallion Series technology incorporates an altered ball/seat check-valve assembly to allow for solids passage. Its polyurethane screen base at the inlet gives added durability.

Contact us to learn about how we can help you with your pump needs.

CALL US NOW EMAIL US