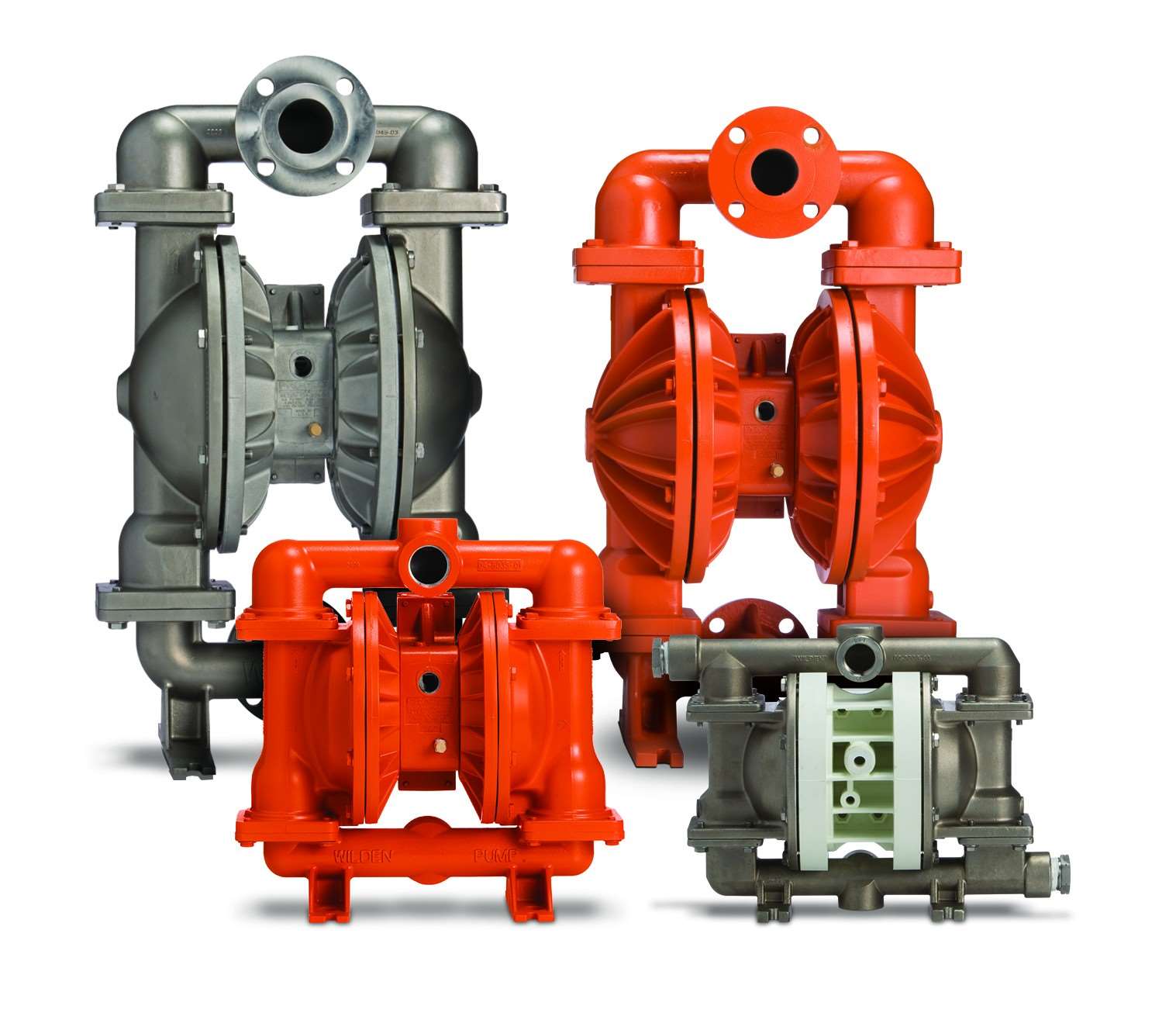

The Wilden® bolted metal pump, also known as FIT, sets the new standard for pump performance. Featuring an enhanced flow path design, Wilden’s bolted-construction pumps offer improved flow rates (up to 35% over competitive models) as well as improved diaphragm life. Wilden’s bolted pumps are also designed for superior containment and have the exact bolt down footprint and inlet/discharge connections as Wilden clamped pumps for easy replacement.

Contact us to learn about how we can help you with your pump needs.

CALL US NOW EMAIL US